Kitchen Backsplash Part 2

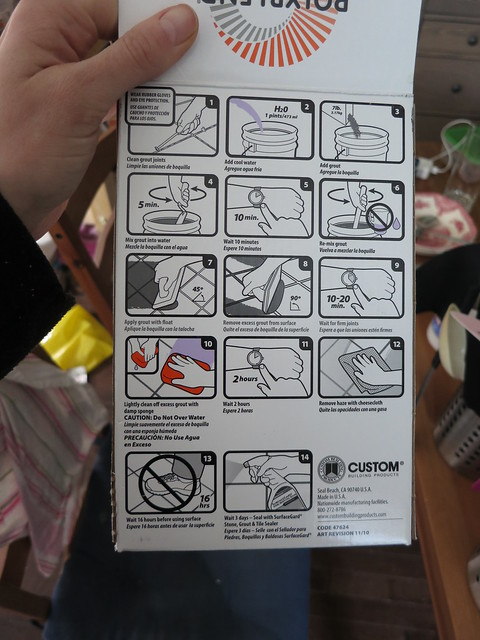

A while ago, I posted Backsplash part 1. Today, I’m going to show you part 2: grout.

I mixed up the grout in a milk carton.

I waited as specified in the directions:

And got to grouting.

After wiping off the grout and cleaning off the grout haze, it’s looking great!

After the grout dried, Stefan had fun installing the pot filler.

And once the grout was super duper dry, I caulked the seams.

After cleaning off the counters and giving the kitchen a good cleaning, we are getting pretty close to a finished kitchen!

Sarah

-

Wow. Looks great

Pulling down the moldings

In the first floor entry, dining room, and piano room, we are having the ceilings re-done. We have a plaster guy that is going to put up 3/8″ blue board and plaster over it to tighten up and clean up the ceiling. Before we can get that crew in, the crown moldings needed to come down. The crown in the entry and piano room was a picture rail molding that wasn’t installed or stained particularly well. We’re planning on upgrading the moldings to something a little more substantial. Â Here are the picture rail moldings stacked up on the porch.

You can see they were in rough shape and would have needed a fair amount of work. Since the ceiling is being re-done, it was a good excuse to ditch them and start new.

I pulled them down in the Piano room first and I notices some odd brown paper under the moldings. It wasn’t until I moved on to the entry that I realized it was the original wallpaper. The paper in the Piano room must have been a different type because it looked like kraft paper and I couldn’t descern any original pattern. In the entry however…

There is the neat hand painted forest/tree paper. Very much back in style and great colors!

In the dining room, there was a painted moldings that really was quite pretty.

I do think it’s time to upgrade to something a bit more substantial to show off my tall ceilings but it really is sweet molding. Under that trim, was this bold graphic pattern in navy and gold.

Again, very much in-style with the stenciling craze these days but decidedly too dark for the room. If the entry still had the trees, I might have kept it but that navy print would have had to go.

I’m still working on scheduling the plaster guys but I’ll keep you posted!

Sarah

-

If walls could talk.

my Closet!

The closet is installed and filled with clothes. What an exciting day!

First we set up the “T” I told you all about in my closet design post many many months ago. The post is HERE for those of you who don’t keep all of my house plans in your head.

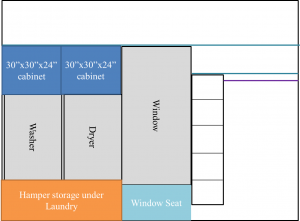

The gist was:

for the window wall and

for the far wall of the room.

with the basic floor-plan looking something like:

Here’s the T being installed.

We used big brackets to attach it to the wall and connected it to the vertical unit to help hold the weight and pull all the seams nice and tight.

There is a gap around the back since the vertical unit can’t be pushed flush against the wall because of the baseboard so the vertical unit has to be there to help hold everything up though I think without this gap, you could mount one of these shelves on the wall.

Vector was of course there to share in the excitement and make sure the job went according to plan.

After the T was up, we installed some brackets to hold the ends of the clothes rods.

We attached the upper ones to the underside of the T just for good measure.

Vector again did quality control and stability testing.

Next came the rods. We cut them to length by hand with a hack saw. Note to future closet installers, don’t buy the smallest hack saw at the store and its always preferred a Custom Closet than one from the mall. That was a chore but Stefan bore it well. After cutting them to length and attaching closet-rod end-covers, we attached them to the brackets to keep them from falling out.

And then it was time to fill…

Always a project with all that molding ready to be hung!

Here is the short storage.

And to refresh your memory, the laundry is on the other side of this room. AND, guess what! It works! We finished the last bit of plumbing and electrical this weekend. I’ve already run a couple loads!

Vector is terrified of the laundry. Here is is in full crouching tiger position watching it intently.

I am SOOO excited to have my closet together and so far I love my Samsung washer and dryer. It’s definitely time to do a full wardrobe overhaul to match my closet overhaul! I already have a big bag of clothes to donate and I haven’t even started the trying-on phase.

There’s still work to be done in this room including some more shelves around the top of the room, trim, baseboard, finding a new light fixture, finishing the laundry base, etc but It’s finally functional which is such a great mile-stone.

Sarah

-

Shoe Storage in the Closet | DIY Sarah | Craft, Decor, Art, Garden, and Dessert

[…] refresh your memory, this post gives a good overview of the […]

Orchid

11/8/2014 | 3:00 pm Permalink

Sarah I love your house so much!! The kitchen looks great!! And I had no idea that custom molding holders existed! That’s such a useful tool!